Facilities

Lorem ipsum dolor sit amor

A properly constructed and maintained restaurant will make it easier for you to prepare safe food for your customers. Always consult with your local health department before you:

- begin construction;

- convert an existing structure into a food establishment;

- remodel or renovate an existing food establishment; or

- make minor structural repairs.

It will save you a lot of time and money if you check first to make sure that what you are proposing is acceptable.

Plan Review

If you open a new restaurant, you typically will undergo a plan review. As part of the plan review, you will need to submit the following to the local health department:

- Menu

- Volume of food to be stored, prepared, sold, or served

- Proposed layout, mechanical schematics, construction materials, and finish schedules

- Proposed equipment, including manufacturer, model number, locations, dimensions, performance capacities, and installation specifications

- Written standard operating procedures

- Other information required by the local health department

Facilities Requirements

Construction materials used in your restaurant must be easy to clean and be acceptable to the local health department. Floors, walls, and ceilings should be smooth, nonabsorbent, and in good repair. Floors should also be wear–resistant, slip–resistant, and nonporous. Floors also need to be graded to drain. Carpeting and other absorbent floor materials cannot be used in areas subject to moisture, such as food preparation and dishwashing areas, because these materials are not easy to clean.

Equipment

Equipment must be made from materials that are:

- safe;

- durable;

- corrosion-resistant;

- nonabsorbent;

- sufficient in weight and thickness to withstand repeated washing;

- smooth and easy to clean; and

- resistant to pitting, chipping, crazing, scratching.

Equipment surfaces that are not designed to come in contact with food (also known as nonfood–contact surfaces) must be smooth, nonabsorbent, corrosion–resistant; free of unnecessary ledges, projections, and crevices; and constructed to be easy to clean and maintain. Surfaces that cannot be routinely cleaned and sanitized because they are not properly constructed could be a source of harmful microorganisms.

Equipment surfaces that are in poor repair are also difficult to clean. Food that is prepared on or in them can become contaminated. For example, cutting boards that become scratched are more difficult to clean and sanitize. As a result, harmful microorganisms might be present on the cutting board. These microorganisms may then be transferred to foods causing the food to become unsafe to eat.

Equipment and utensils must also be constructed so that parts do not break off and end up in food. For example, pieces of wood from a utensil made from soft wood could break off into food and possibly cause injury to a customer who eats the food.

Properly maintained equipment helps ensure that it will operate as designed. For example, a refrigerator that is not properly maintained might not be capable of properly cooling or holding potentially hazardous foods at 41°F (5°C) or colder. Other things to consider when selecting equipment include:

- Portable equipment is often easier to clean and clean around than permanently installed equipment.

- Stationary equipment must be mounted on legs that are at least six inches off the floor or sealed to a masonry base.

- Stationary equipment that is mounted on legs that are on a tabletop must be at least four inches between the base of the equipment and the tabletop.

- All cracks or seams over 1/32 inches must be filled with a nontoxic, food–grade sealant.

- Select equipment that has a NSF International mark or an Underwriters Laboratories (UL) product mark. The presence of either mark on foodservice equipment means that it has been evaluated, tested, and certified as meeting international commercial food equipment standards.

Lighting Requirements

Position lights above workstations so workers do not cast shadows on their work surface. Light bulbs must be shielded, coated, or shatter–proof in food preparation areas. Shielding of light bulbs helps prevent breakage. Light bulbs that are shielded, coated, or otherwise shatter–proof are also necessary because they protect exposed food, clean equipment, utensils and linens, and unwrapped single–service articles from glass fragments if the bulb breaks.

Walk–in refrigerators or freezers and dry storage must have 1110 lux of light; in self–service bars or where fresh produce or packaged food is displayed there must be 220 lux of light; and in food preparation areas there must be 550 lux of light. A foot–candle is a unit of measure of the intensity of light falling on a surface. It was originally defined as the amount of light given off from a candle burning at one foot from a given surface.

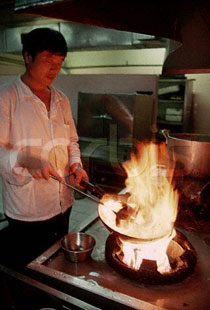

Ventilation Requirements

Fresh air, at correct temperatures and humidity, is essential to worker comfort. The ventilation system in your restaurant must meet local regulations and be properly constructed, properly maintained, and properly cleaned. The dripping of grease or condensation onto food could contaminate food.

Linens

Linens are fabric items, such as cloth hampers, cloth napkins, wiping cloths, and work clothes. They must be stored in a clean area. Wash them in a washing machine and then dry in a dryer. Linens cannot be air–dried in the restaurant. Wiping cloths can be washed in a sink.

Water

All water used for drinking, food preparation, and washing must be from an approved source. Many restaurants get their water from a public water system. All public water systems must meet national drinking water regulations. Nonpublic water systems must also meet state drinking water quality standards. Check with your local health department about local regulations regarding your water supply. A non–drinking water supply can only be used if its use is approved by the local health department. If approved, it can be used for air conditioning, nonfood equipment cooling, fire protection, and irrigation.

The water source, including hot water, must meet the peak water demands of the establishment. Water under pressure must be provided to all fixtures, equipment, and nonfood equipment that require water. Alternative water supplies include bottled drinking water, closed portable water containers, enclosed vehicle water tank, or on–premises water storage tank. In the event of an emergency that causes the water in your restaurant to become unusable, follow these guidelines:

- Use bottled water.

- Boil water (check with your local health department first).

- Purchase ice.

- Use boiled water for essential cleaning or use single–use items.

Plumbing

Improperly maintained plumbing has been documented as the cause of many foodborne illness outbreaks. Plumbing in your restaurant must meet local regulations and be properly constructed and properly maintained.

Cross–connections

A cross–connection is a physical link through which contaminants from drains, sewers, or other wastewater sources can enter a safe water supply. A faucet located below the flood rim of a sink is an example of a cross–connection. Properly installed plumbing will prevent this from happening in your restaurant.

Backflow Prevention

An air gap can prevent the backflow of unsafe water into a safe water supply. An air gap between the water supply inlet and the flood level rim must be at least twice the diameter of the water supply inlet but not less than one inch. If a backflow (or backsiphonage) device is installed, it must meet American Society of Sanitary Engineering (ASSE) standards.

Grease Condensation and Leaking Pipes

Grease traps must be easy to access, installed by a licensed plumber, and cleaned on a routine basis. Overhead wastewater pipes or fire safety sprinkler systems can leak and become a source of contamination. If leaking occurs, have the piping immediately serviced.

Other Plumbing Considerations

All restaurants must have at least one handwashing sink, one toilet, and one urinal. At least one service sink or one curbed cleaning facility equipped with a floor drain for cleaning of mops and disposing of wastewater must be installed.

Handwashing sinks must provide hot and cold running water at a temperature of at least 100°F (38°C). Automatic handwashing sinks must be installed according to the manufacturer's instructions. Handwashing sinks must also be conveniently located in food preparation areas, service areas, warewashing areas, and restrooms. They must also be equipped with signage indicating that workers are required to wash hands before returning to work.

Garbage Disposal

Provide garbage cans that are large enough to handle all garbage. Clean cans at least once a week. Remove garbage from food preparation areas often. Waste materials and empty product containers are unclean and can attract insects and rodents and so need to be removed from the establishment frequently.

Sewage

Adequate drainage must be installed to handle sewage and wastewater. Areas with a lot of water exposure, such as where dishes are washed, must have floor drains. A backup of raw sewage is cause for immediate closure of the establishment. The problem will have to be corrected and the establishment thoroughly cleaned before it can be reopened.

Prepared by: Angela M. Fraser, Ph.D., Associate Professor/Food Safety Specialist Department of Family and Consumer Sciences NC State University, Raleigh, NC 27695-7605